|

About six months ago, I acquired a Chickering grand with some issues but a lot of promise. Originally built in 1921, it had a beautiful finish on the case and a pretty nice tone. At some point, cosmetic work had been done to make it look nice. However, the soundboard had some issues and the original action was worn out and showing the effects of nearly 100 years of being played.

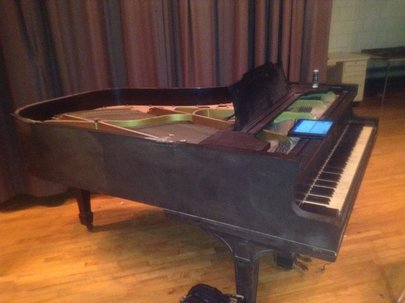

One of the really fun features of the piano was that it had been built as a player piano. The double legs in the front gave it away!. The original piano roll player was long gone and had been replaced with a QRS player system. The plan for this piano is to repair and refinish the soundboard, replace the old action with a new, WNG action, new hammers and upgrade the QRS system to the newest PNOmation3 system.

1 Comment

Earlier this month, I delivered back to its owner, a 1924 Baldwin Model M grand (6'1") after an extensive restoration.

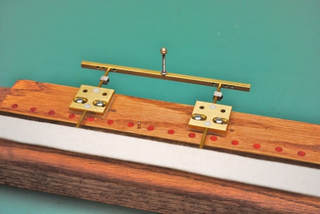

This piano lives in one of the common rooms of a church in Brookline, MA. It is used nearly every day by piano teachers, art groups, an itinerant opera company and members of the parish. It was cared for reasonably well and some improvements had been made in the past few years like new keytops and hammers. But, after many years of use (and abuse), it was in need of more serious work. As you will see in the pictures, the piano was in sad shape. The case was poor condition and the interior looked worse. The soundboard clearly had a number of bad cracks and a lot of liquid damage (spilled coffee and drinks, mostly). The pin block was in bad shape. Tunings didn't hold very well. String were rusted. The plate was just ugly with more spills, scratches and lots and lots of grime. This week I had an interesting challenge in polyester finish repair. Repair a large chip of finish on the vertical face and corner of the arm of the piano. The pictures really show the problem; and the results. The solution is not gluing in the broken out piece and then filling in around it. When does that ever work? The correct solution is building up the fill from bare wood to just below the final level with the gel poly. Then, after building a form or "dam" with plastic sheeting, filling it with the liquid poly. The fun was shaping it all so that it looked like the original corner profile. Further sanding and polishing brought it all back to near original high gloss finish. A good couple of days work.  This week, I installed a Grand Piano Muffler in a new Cunningham Parlour Grand. This is a unique product for grand pianos. Muffler rails are not an uncommon feature in upright pianos built by Yamaha or Kawai. They allow the player to lower a piece of felt between the hammers and the strings, reducing the volume of sound quite dramatically. They are perfect for apartments or homes to allow practicing any time of day without disturbing neighbors or sleeping children. The Grand Piano Muffler was invented by Steven James and fills a real need for many pianists. It's a very clever system with custom made brass rails and a piece of felt that, when moved into position between hammer and string, reduces the volume of the piano over 80%. The system is custom made for each piano. It's simple to use and very effective. The Grand Piano Muffler works well with both the QRS PNOmation3 system and PianoDisc's player system. For more information, click here. After a few months of frequent tunings and repairs, it was decided that some real work needed to be done to make this piano reliably playable. One could certainly argue that a complete rebuild could be done to bring the piano up to a good standard. But that was not in anyone's budget!

Looking at the piano in its current condition and at the list of recurring problems it was decided that new strings and tuning pins would be the best improvement. A good cleaning and regulation of the action was included. Once school was out for the summer, work would commence!  This Weber BB grand, built in 1918, was found to be in sad shape. Located in a high school auditorium in the Boston area, it hadn't been used or tuned for many, many years. A new administration and new music teacher wanted to get it playing again. This turned out to be a much larger project than expected but the results will bring new life back to this tired instrument. This will be an instrument the students will look forward to playing. The first steps with this piano were to bring the piano to pitch and to some sort of working condition. The first tunings were rough with a major pitch correction. Tuning pins were all over the place in their ability to hold tension - some were tight, some were loose. After a couple of months of tuning, the piano was starting to hold and sound better. I should correct something. The first steps with this piano was not tuning but cleaning. OMG! It was unbelievably dirty. Almost Haz-Mat dirty. All sorts of trash was found in the piano and a number of drinks had been spilt in it over the years. Part of the lid is missing so there is no protection from dirt, dust and the naughtiness of kids. Fortunately, no vermin! (Another piano was trashed due to extensive damage from neglect, vandalism and vermin.) A major clean and tunings though got this piano to a point where the teacher was using it regularly. Something not done in the school in 20 years! Yay! |

AuthorJohn Totter is the owner of The Piano Practice, a Full-Service Piano Care company serving Rhode Island and Metro Boston. CategoriesArchives

April 2019

|

RSS Feed

RSS Feed